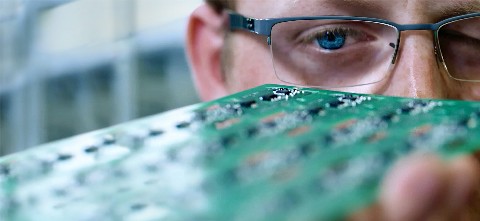

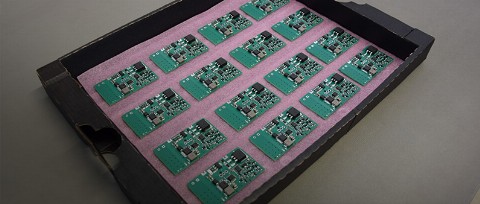

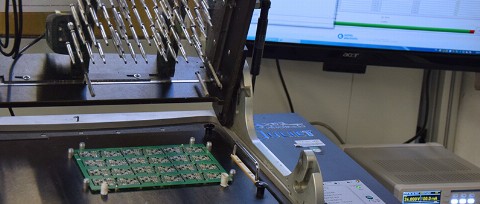

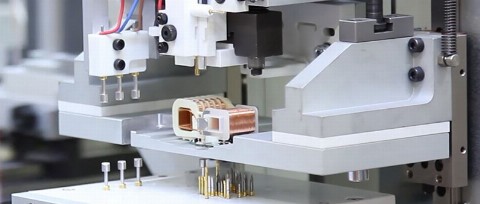

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines.