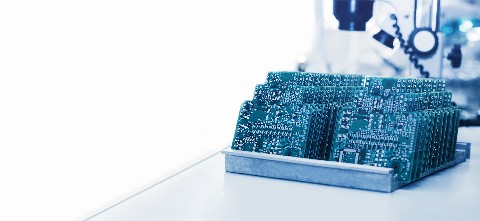

Highly flexible high-end circuit board assembly, made in Germany and the USA. Automated manufacture and testing technology alongside top manufacturing organisation are our answer to the ever growing complexity of EMS requirements today. You can profit from our immediately scalable production solutions for practically every place of deployment – everything from one supplier in top quality and at attractive prices.

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions.

3D soldering paste inspection

– 3D-SPI solutions on every SMT line

– Shadow-free 3D measurement

– Closed-loop software for template printer and 3D-AOI

– In use: 8030-2C / Koh Young

Reflow soldering technology

– Efficient reflow convection soldering processes

– Soldering processes under protective gas atmosphere

– The highest process stability

– Minimisation of thermal loads

– In use: VXP+ N2 3500 / Rehm Thermal Systems

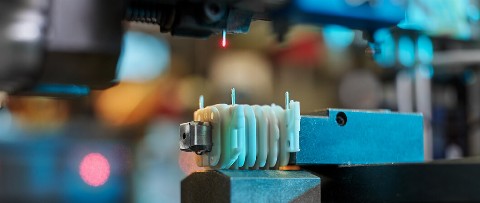

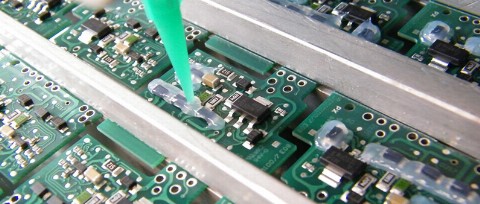

Dispensing technology

– High process security even where there are temperature & viscosity deviations

– Optimal dispensing results in the critical starting & stopping range

– In use: PR1750 / Datron & WRa500OPT / Globaco

Stencil printing

– The latest template soldering paste printers

– 3D paste inspection

– Secure placement of the tiniest parts

– In use: NeoHorizon 03iX / DEK

SMT mounting

– Scalable quantities

– Siplace mounting plants by ASM in use

– Choice of SMT forms 01005 to 2220

Automatic optical inspection (AOI)

– 100 % inline testing

– Linking of the results of 3D-SPI with 3D-AOI system

Inline programming

– Test & programming service

– Secure & precise contacts

– High pin density & design for individual later upgrades

– Flexible choice of programs almost right up to the start of production

– On PRÜFREX production lines or in your in-house final assembly

– In use: Rapido RPS910 / Göpel Elektronic

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines.

Soldering technology

– Selective, reflow or laser soldering

– Manual soldering or soldering with Cobot support

Wave soldering

– Soldering carried out under nitrogen

– Infrared pre-heating zones with upper heating & temperature monitoring

– Fluxer area with external module incl. fluxing agent quantity monitoring

– 2-nozzle soldering module, residual oxygen measurement

– In use: Wave soldering plant MWS2340-LRT / Seho

Assembly lines

– Fully automated plants for mass production requirements

– Economic, on-deadline & highly efficient component assembly

– In use: Aumann AG & Marsili plants

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for your comprehensive tasks. Our coils are tinned with lead-free coatings (RoHS).

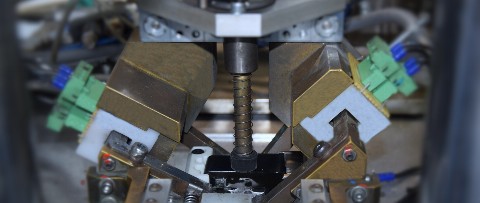

Multiple spindle fine wire winding technology

– Automated high-speed winding (0.045 mm to 0.71 mm)

– Secondary coil & charging coil winding machines

– In use: Marsilli

Cable construction

– Automated work processes

– Cutting of the ignition lead, up to 3x bending of the contact

– Pressing of the contact pin into the dome

– Processing of cable lengths from 124 mm to 350 mm

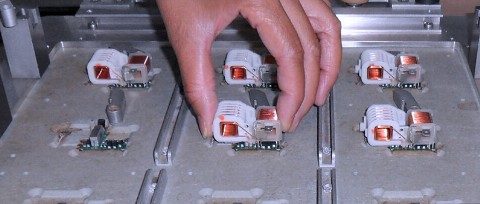

Coil assembly

– Automated work stages

– Feed-in of partially assembled components & workpiece holders

– Placement and removal of eight mandrels

– Multiple material provision via vibrating platform

– Visual determination of coordinate parameters

–In use: Universal Robots, 3-axis vibration technology FlexCube 380 & SmartSight